Ford’s Advanced Manufacturing Center is utilizing futuristic technologies to innovate the manufacturing process

Today (December 4th, 2018) I had the opportunity to visit Ford’s Advanced Manufacturing Center located in Redford, Michigan. This 100,000 sq. ft. facility is a $45 million investment into Ford’s manufacturing future.

Over 100 years ago, Henry Ford changed history forever by creating the assembly line. Today, Ford is utilizing futuristic technology to create new manufacturing processes that could change history once again.

Inside this gigantic facility, I saw advanced robotic technologies, 3D printing, virtual and augmented reality. All of this seemed a bit overwhelming at first because I’m not familiar with this type of technology. I quickly picked up on the advantages Ford could benefit from by utilizing these types of new technologies.

3D printed parts will be used on the 2020 Shelby GT500

The soon to be released Shelby GT500 is the second automobile Ford has utilized 3D printed parts on. The GT500 is fitted with a pair of of brake line holders that were traditionally created out of metal. I spoke with one of the engineers after the tour and asked a few questions about this specific piece. He told me that this brake line holder could be created in a batch of 10-12 pieces and ready to be installed within 2 hours time. Not only does this cut material and tooling costs, it is a huge time saver!

Ford purchased the third 3D printer ever made in 1988, today they now have over 90 3D printers globally that produce parts and tools. The first 3D printed part to make its way onto a production vehicle was on the Ford F-150 Raptor. The piece shown below was created for Raptors exported to China that fills a hole where buttons would normally be on the U.S. model Raptors.

Ford used five different 3D printed tools during the production of the new Ford Ranger. I was shown a few examples which included a tool that was used to place the Ranger’s driveshaft into position on the assembly line, set the distance between the bed and the cab and a lift assist used to align the transmission.

The 3D printed tools used on the transmission lift assist saved Ford roughly 2 million dollars and precious assembly line real estate. That is huge! This is just the tip of the iceberg when it comes to how these new technologies can be used throughout the manufacturing process.

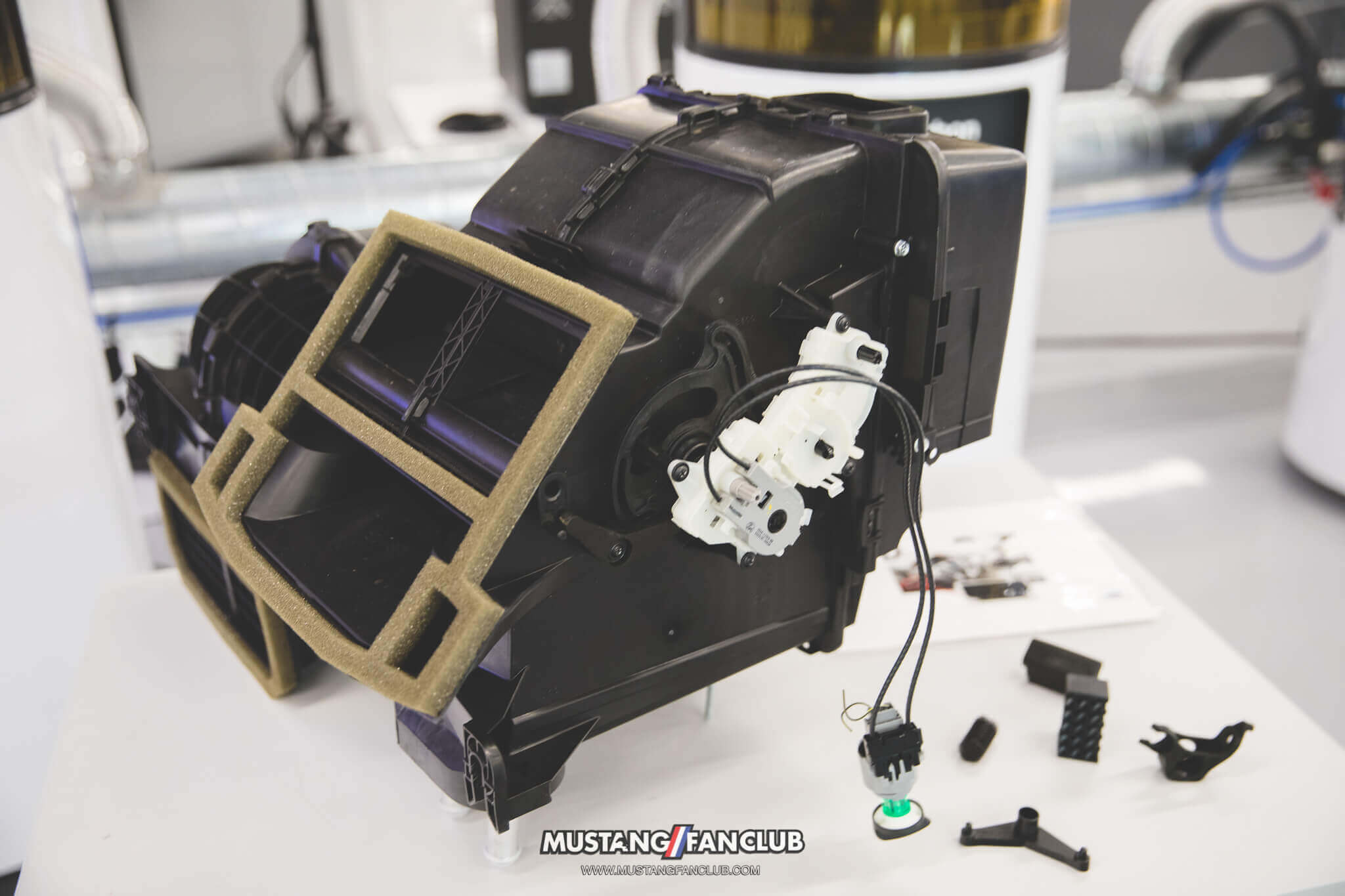

The third 3D printed part Ford has been working on is a heater control lever replacement part for an early model Ford Focus. I know it may not sound exciting but this could potentially be huge for Ford’s replacement parts department. With no tooling required for 3D printing, Ford could essentially “print on demand” for many replacement parts in the future.

The V-8 engine will continue to be a part of Mustang’s DNA

The V-8 engine still has a future with Mustang

The guys from StangMode had a chance to chat with the CEO of Ford Motor Company, Jim Hackett. It’s apparent at this point that hybrid and electrification of Ford automobiles will be upon us in the near future. With that in mind, will our beloved V-8 Coyote engine be dismissed from the Mustang? RIP 3.7L V6 Cyclone.

StangMode asked Mr. Hackett if there will be a future for the V-8 engine and his response was YES! Jim mentions that he and Bill Ford have had discussions about the Mustang. They understand that there are certain things us Mustang enthusiasts will accept when it comes to Mustang. We can’t have history repeating itself when the Mustang almost became front wheel drive (Probe).